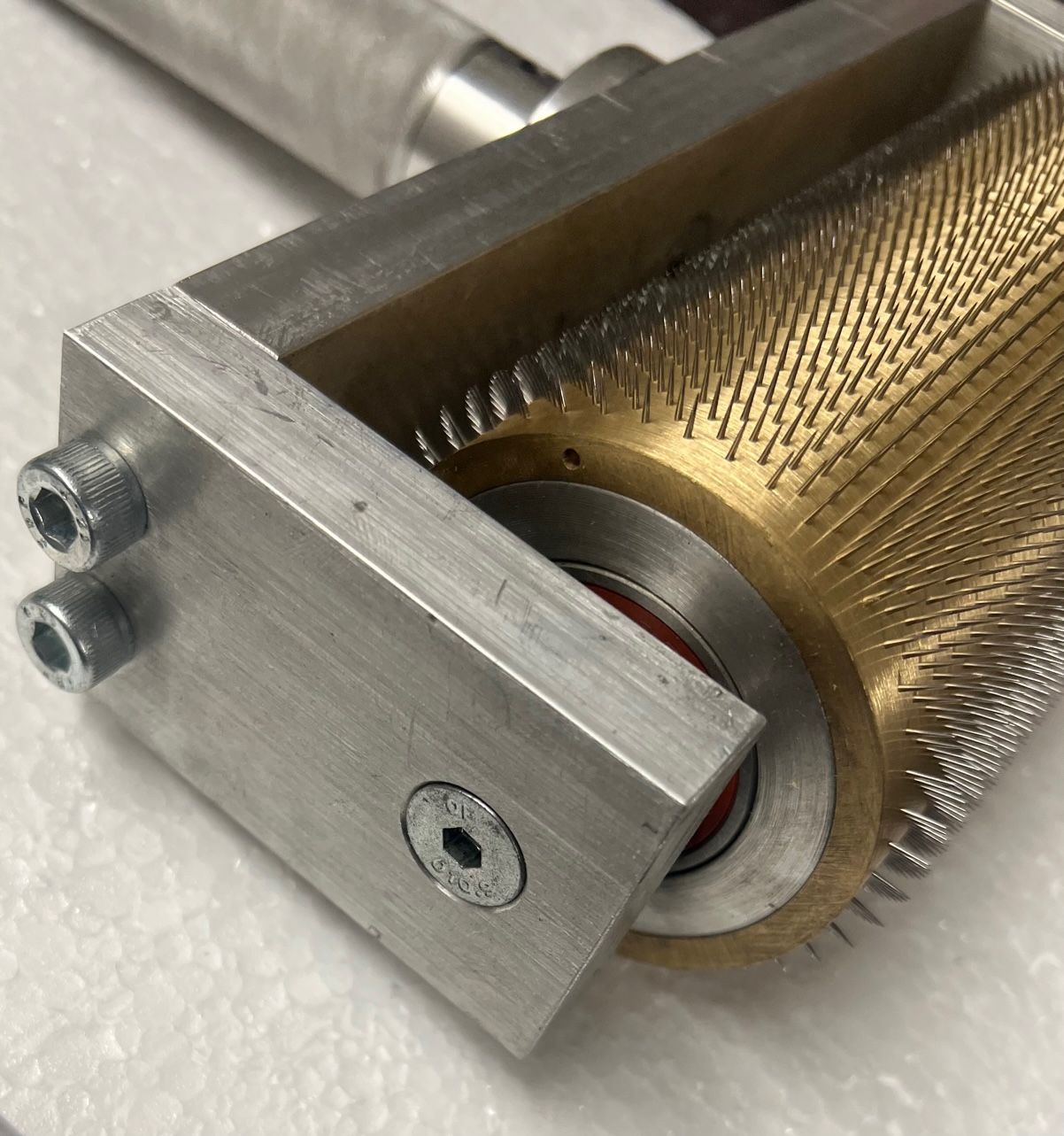

Our manually operated perforation devices are custom made to a clients' requirements.

This is ideal for cost-effective trials, pattern density testing and manual perforation.

We manufacture many of these units for a diversity of applications

Some examples are

Air and moisture elimination (Composite Prepreg Lay Up Tooling)

Heat Dissipation (Tyre needling)

Gas bubbles & pin point removal (The use of spiked rollers help to level and homogenize epoxy floor screed before curing)

Porcupine Rollers for use in conveyor belt splicing

And many more...

We manufacture 2 different types of Hand Operated Perforation Rollers.

Our standard size pinned unit is 60mm Inside Diameter & 70mm Outside Diameter, but we are happy to accommodate any configuration

Handheld Perforation Enquiry

To accommodate individual client requirements, we offer

- Rollers in Steel or Brass

- Custom Pin Densities and Patterns

- Custom Needle Diameter, Length & Protrusion

- Standard Carbon or Stainless Steel Pins.

Both types are supplied with working bearings and are interchangeable for pattern testing.