Hot Needle Perforation

Hot Needle Perforation creates small holes in modern materials like LDPE, LLDPE, HDPE, and PP.

This technique makes perfectly round holes that are heat sealed around the edge, keeping the strength and durability of the material intact.

Hot Perforation Machines come with interchangeable pin segments and a needle depth adjuster, allowing for precise adjustments to the hole size.

These machines have an automatic warm-up timer and speed control that matches the web speed, ensuring accurate and round holes. They also feature an automatic cool-down system.

Safety is a priority with the Hot Needle Perforation Machines, which include protective guards, an emergency stop, a heat shield to protect the web, and a remote control station for easy operation.

The Perforators can be easily integrated into your existing systems, like slitter rewinder units and film blow lines.

Cold Needle Perforation

Cold Perforators feature pin segments that can be easily switched out. These segments are available in different perforation patterns, including square, diamond, and spiral, along with other designs based on customer needs.

The machines work by opening and closing with air pressure. They have complete safety features and are built strong for durability.

This is a complete unit designed for creating holes in polythene, PVC, paper, and other appropriate materials.

These are perfect for single wound, lay flat tubes or gusseted films with a maximum working width of six meters.

Intermittent Perforating

The Intermittent perforation unit is fully enclosed and designed for hot perforation of materials like polythene, polypropylene, metallized film, and various synthetic substances. It can operate at speeds of up to 400 cycles per minute and handle a working width of up to 2 meters, producing up to 200 meters per minute.

Key Benefits:

- Print register: This machine can perforate accurately according to a printed register mark.

- Pre-set lengths: It allows for perforation at specific lengths, which can be adjusted on the control panel.

- Intermittent mode: It can run in intermittent mode at speeds up to 400 cycles per minute.

- Manual mode: When set to manual, it functions as a standard perforator.

- Solid state heater controls: Equipped with both internally and externally heated pin rollers to enhance production speed.

- Timer: Features a timer for automatic warm-up, eliminating wait time for the heater.

- Automatic speed control: The perforator adjusts its speed to match the web speed for consistent round holes.

- Automatic cool down: The machine automatically turns off when it cools to a safe temperature.

Core Cutting

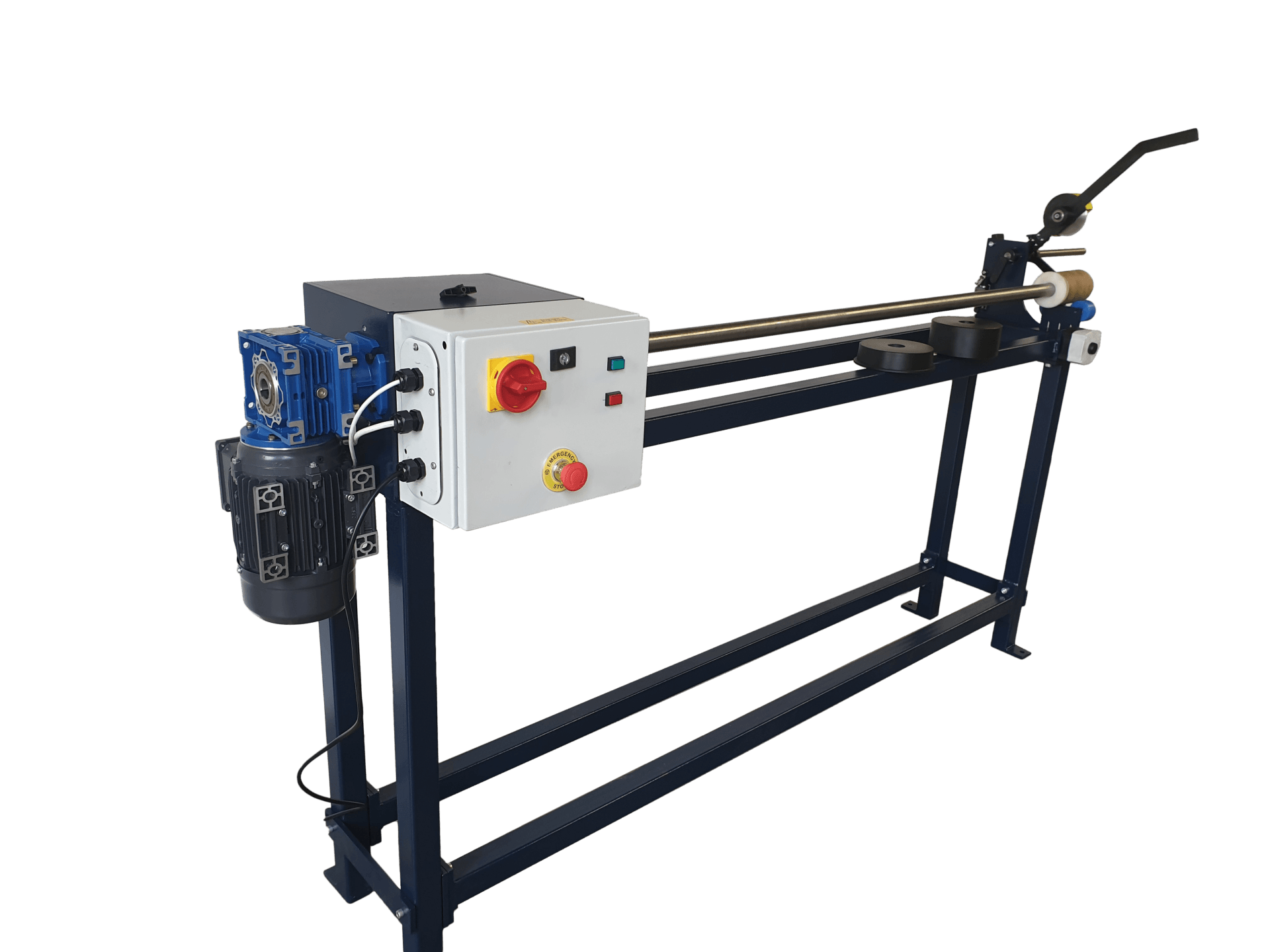

The 1600mm manual core cutter designed & built by Heritage Engineering NW Limited can cut through plastic and cardboard cores specifically for the paper converting industry.

The model displayed is designed for a core with a diameter of 3 inches. It features a centrifugal core grip and supports that utilize a crush knife cutting method.

This machine can be adjusted to fit different core sizes, reaching up to 6 inches in diameter, and can also be customized in length to meet customer needs.